Crimped Wire Mesh: The Backbone of Industrial Filtration

Crimped wire mesh, a stalwart in the realm of industrial filtration, serves as the robust foundation for many filtration processes. This article delves into the world of crimped wire mesh, exploring its structural composition, applications, and how it forms the backbone of industrial filtration systems, ensuring efficiency and reliability in diverse industries.

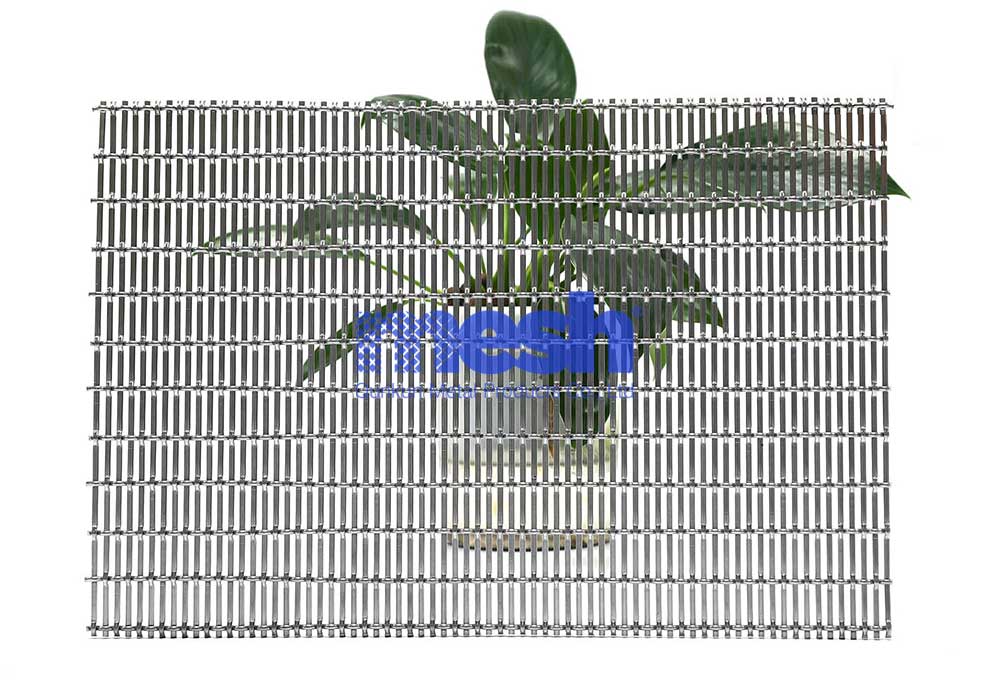

Understanding Crimped Wire Mesh

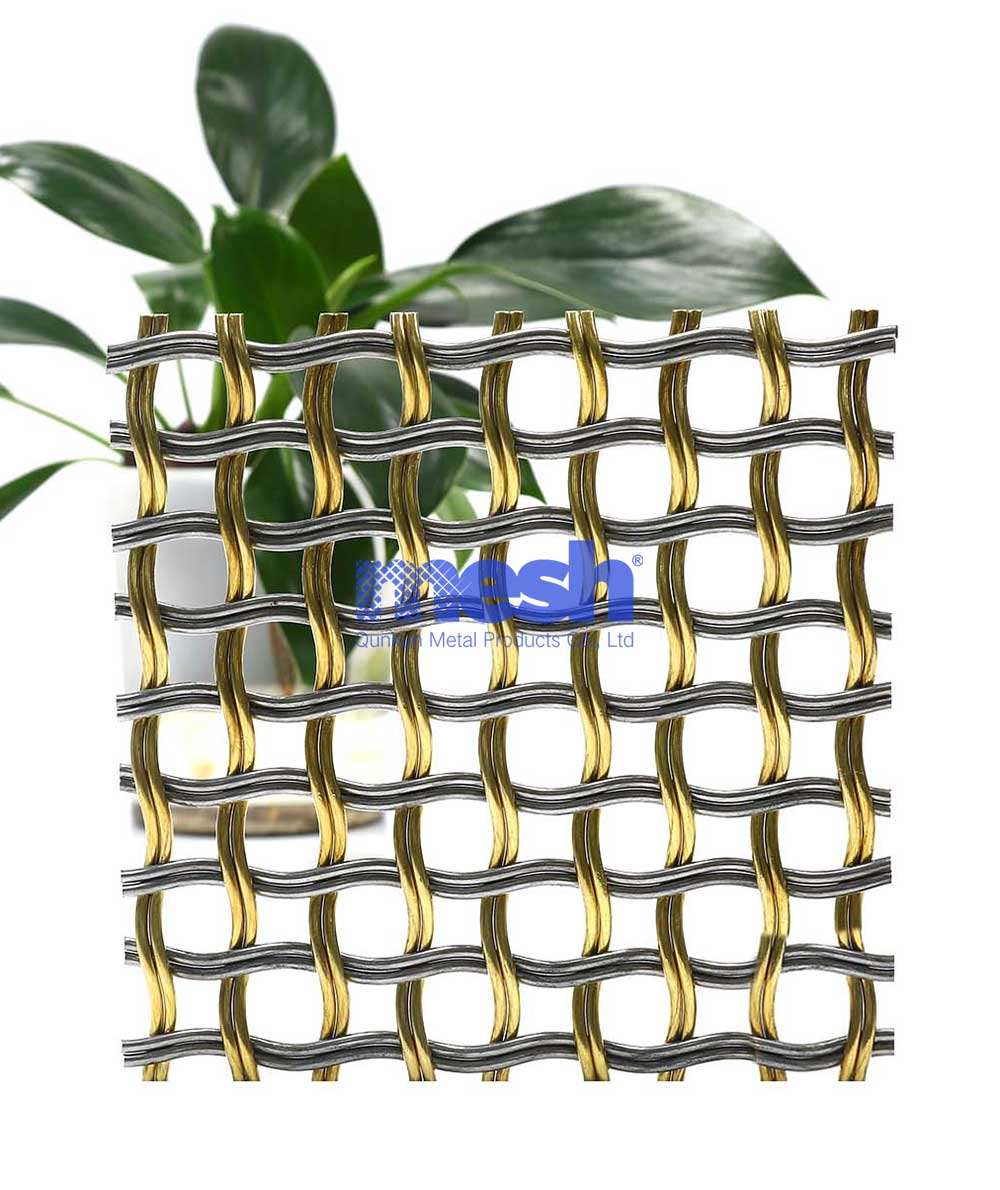

Crimped wire mesh is a woven mesh composed of high-quality wires that have undergone a crimping process. During crimping, the wires are shaped to have corrugated patterns, enhancing their stability and strength. This crimping pattern creates a resilient and durable mesh suitable for heavy-duty applications.

Structural Composition and Strength

The structural composition of crimped wire mesh is vital to its strength and longevity. The crimping process significantly increases the wire's tensile strength, enabling the mesh to withstand substantial pressures and forces. This enhanced strength is the backbone of its application in industrial filtration, where it must endure the rigors of filtering various materials.

Crimped wire mesh stands as the unsung hero in industrial filtration, providing the sturdy foundation needed for effective sieving and separation of materials. Its crimped structure, durability, and versatility make it the backbone of filtration processes in various industries. As technology advances and industries progress, the significance of crimped wire mesh in industrial filtration is set to grow, ensuring efficient and reliable filtration processes for years to come.

-

Best Welded Wire Mesh for South American Markets Feb 03, 2026

Best Welded Wire Mesh for South American Markets Feb 03, 2026 Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China